For the past few hundred years, industrial metrology has been an important part of the manufacturing and processing businesses. It has changed a lot over time, just like technology. With each step forward, things get better, faster, and more useful.

High-tech measuring tools today use AI, IoT, and robots to do their work. This changes how companies work in a big way. There is a lot of interesting history behind industrial metrology in this paper.

It goes from its simple beginnings to the advanced methods we use today. Get ready to learn how fast-paced technology has changed this field. Read more!

Contents

History of Industrial Metrology

Industrial metrology ensures the accuracy and quality of various products and operations. Many measurement tools, technologies, and methodologies assist firms follow rules and satisfy customers in this industry. As our methods become more complex, we require more powerful measurement tools.

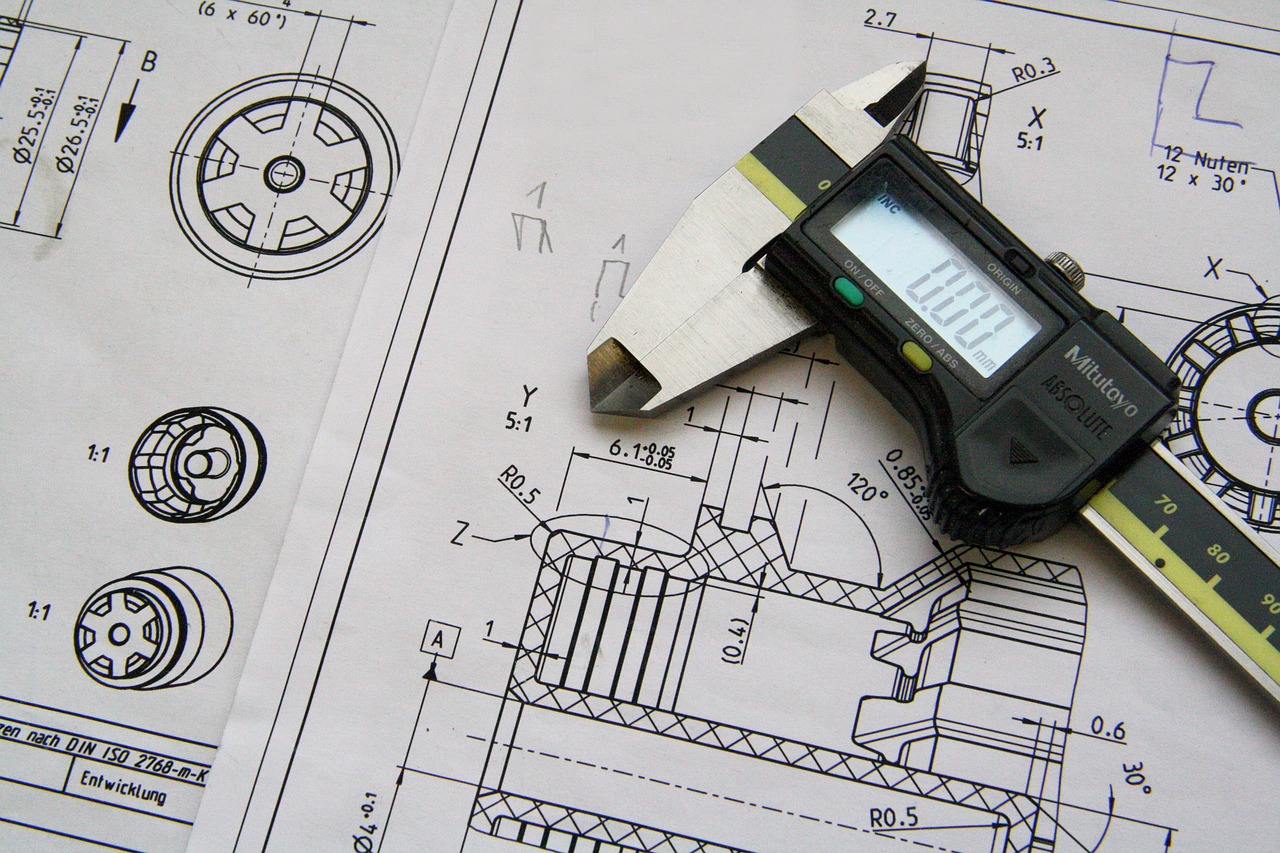

You need to know its origins to measure its progress. Calipers, micrometers, and gauges were used for manual measurements.

This required time and talent. However, a coordinate measuring machine (CMM) improved reading accuracy and speed.

Advancements in Technology

In recent years, industrial metrology has undergone a technological revolution, driven by advancements in computing power, sensor technology, and automation. Let’s explore some of the cutting-edge technologies that have transformed the field:

Computer-Aided Measurement Systems

CAMS are computer systems that help with measuring things. They have precision tools and powerful software that lets you get data, look it over, and show it all at the same time. This is a better and easier way to measure, and you can learn things that will help you make the process better.

3D Scanning and Laser-Based Technologies

Business people can now use lasers and 3D scans to measure things without having to touch them. A laser scanner can give you accurate 3D metrology and help you see surfaces and shapes that are hard to see. You can check the quality, record digitally, and figure out how something works from the inside with this tech.

Robotic and Automated Metrology Systems

Automatic and robotic measurement systems combine the speed and accuracy of measuring tools and robots in a way that works best for them. These systems can measure difficult parts with little help from a person. This makes things run more smoothly and quickly.

Emerging technologies in industrial metrology are beginning to tap into the potential of Silyb Wafers, a new frontier in material science. These wafers offer remarkable stability and precision, proving invaluable in the creation of complex metrological instruments.

Applications in Various Industries

Industrial metrology finds applications in a wide range of industries. Let’s explore how cutting-edge metrology technologies are transforming key sectors:

Automotive Industry

Important car parts, like engine parts and body pieces, need to be the right size. Metrology is used to make sure of this. With the help of new measurement technologies, automakers can make sure that cars are safe and of good quality while still following strict rules.

Aerospace Industry

There is a lot of metrology in making airplanes. It makes sure that the things that go into them are correct and will work. Everything from turbine blades to aircraft parts has to be measured very precisely to make sure they work as safely and well as possible.

Manufacturing Sector

It’s helpful to measure things in business to make sure they are done right and move things along faster. Making things should look for flaws, know why they do things a certain way, and make sure they follow the rules of their business.

Healthcare Sector

Metrology is a very useful skill in the medical field, especially when tools and tests are being made. You need to use correct numbers to make medical items that are safe and useful. Imaging and diagnosing health problems are more accurate now that there are new metrology tools.

Challenges and Metrology Techniques

While cutting-edge technology has revolutionized industrial metrology. It also presents challenges and opportunities for manufacturers and metrology professionals:

Integration of Metrology into Industry 4.0

When Factory 4.0 ideas are used in production, metrology needs to be a part of the digital output. Measuring things with measurement helps us keep an eye on the process, find problems, and improve the end result in real time.

Data Management and Analytics

Poll data is getting bigger and more complicated, which makes it harder to work with. To learn important things and keep making things better, you need to be good with data and know how to use different types of analytics tools.

Training and Skill Development

Manufacturers need skilled workers to get the most out of the most up-to-date measuring tools. People who work in metrology should take classes and work on getting better at what they do so they can learn how to use more advanced tools.

Future Trends

Looking ahead, there are several exciting trends that are poised to shape the future of industrial metrology. These trends hold the potential to revolutionize the field.

Artificial Intelligence and Machine Learning in Metrology

Artificial intelligence and machine learning algorithms have the potential to transform metrology. These tools can measure things, look at a lot of data, and figure out the best ways to measure things so that they are more accurate and better use of resources.

Internet of Things (IoT) and Real-Time Data Collection

It is possible for tracking tools to connect to both IoT systems and production lines. This way, you can always keep an eye on them and tell them what to do. They send and receive info that can help companies find problems, make things better, and make them work better when they are linked.

A Guide to The Evolution of Industrial Metrology

New technologies have changed the past of units used in industry. A lot of things are better now; measurements are more exact, and the quality of the work stays the same. It’s always possible to push the edges of anything, from simple hand tools to high-tech systems that can measure without touching anything.

This lets fresh thoughts come up. People who study, make, and come up with new technologies need to know about these changes in order for industrial measurement to work well. It can help our business by giving us new tools, ways to solve issues, and money-making chances.

Did you find this article helpful? Don’t worry, we have more! Browse our site for more informational and entertaining articles that could guide you!