In a world where electronics are central to every aspect of our lives, the slightest flaw in a single component can lead to system failures, data loss, and a tarnished brand reputation. This common nightmare for manufacturers and consumers alike is where component tester services step in. They offer a shield against the cascade of consequences that can arise from defective electronic parts.

These services don’t just identify the problems. They anticipate them and provide solutions before a product ever leaves the assembly line. With every company’s reputation hinging on the reliability of their products, understanding the pivotal role of component testing becomes not just a technicality but a cornerstone of customer trust.

Read on and explore the seven reasons why these services are not just beneficial but essential for any electronics-related enterprise.

Contents

1. Assurance of Quality and Reliability

When we talk about the heart of a successful electronic device, we’re really talking about its components. Think of them like the internal organs of a human body. If one fails, the whole system suffers.

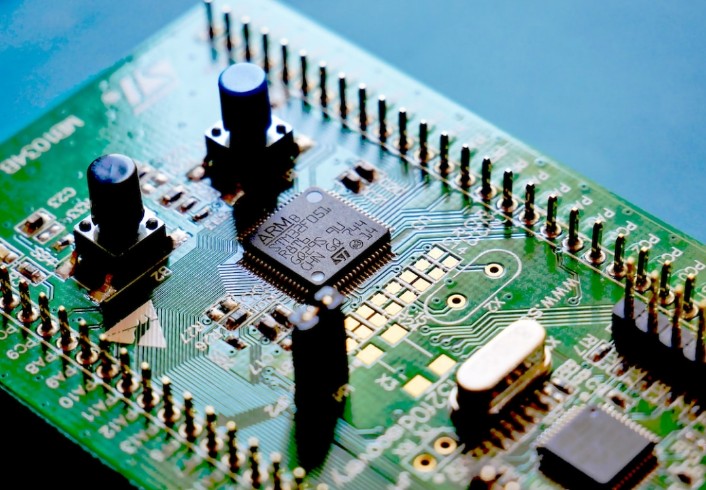

That’s where component tester services come into play. By rigorously examining each part, from the smallest capacitor to the most critical microchip, these services ensure that every electronic part works exactly as it should.

The reality is when electronic parts work flawlessly, the devices they power tend to have a longer life and better performance. This means fewer returns, less frustration, and happier customers.

It’s a simple equation: better testing equals better products. And when customers know they can rely on your products, they’re more likely to stick with your brand. Trust is hard to gain but easy to lose in the electronics industry, and it starts with quality components.

2. Cost Savings in the Long Run

The old saying “a stitch in time saves nine” couldn’t be truer when it comes to component tester services. Some might see the upfront cost of testing as a deterrent, but the reality is quite the opposite.

When you catch issues early, companies can avoid the high costs of a recall, which can run into the millions. Not to mention the potential hit to the company’s reputation.

Think of it as an investment in your company’s future. Every electronic part that’s tested is one less potential failure in the field, and that means real savings.

These services don’t just catch errors; they help prevent the domino effect of related problems down the line. Investing in thorough testing means spending less on customer service issues, warranty claims, and repair costs.

3. Compliance with Industry Standards

The electronics industry is bound by a web of standards and regulations, and for good reason. These rules are in place to protect consumers and ensure fair competition.

However, keeping up with these regulations can be a challenge for any business. That’s where component tester services shine.

Whether it’s a standard for safety, performance, or environmental impact, testing services know the benchmarks that products must meet. They are experts at navigating the often complex regulatory landscape and ensuring that every product not only stands out in the market but also adheres to the necessary guidelines.

4. Reduced Time to Market

Speed is key in the race to get products from the concept stage to the hands of customers. One of the major advantages of investing in component tester services is how they can streamline the entire production process.

By identifying and solving issues with electronic components early on, these services help avoid delays that can happen if problems are only discovered during the final stages of assembly. Or worse, once the product has already hit the market.

This early detection and resolution mean manufacturers can confidently speed up product launches. It’s not just about being quick, though; it’s about being confidently quick.

Knowing that the components have been tested and approved, companies can reduce the overall time it takes to introduce new products.

5. Enhanced Customer Satisfaction

Happy customers are the backbone of any successful business. One key to keeping them happy is ensuring that the electronic components in your products are reliable.

When customers buy a product, they expect it to work not just the first time but every time. Component testing plays a huge role in meeting these expectations.

By using various ways to test electronic components, manufacturers can catch potential issues that could cause a product to fail. And when products work as they should, customers notice. They talk about their positive experiences, and they often come back to buy more.

6. Support for Complex Components

Today’s electronic components are more sophisticated than ever. With that sophistication comes complexity, and with complexity comes a greater need for specialized testing. Component tester services are equipped to handle these complex parts and ensure they meet the design specifications and function correctly in the real world.

These services have the expertise and the technology to support the testing of advanced components and provide a level of scrutiny and technical insight that goes beyond what standard testing procedures might offer. View these value added services for yourself.

7. Risk Management and Mitigation

Risk is a part of any business, but in the world of manufacturing, the stakes can be especially high. Component tester services help companies manage and reduce these risks by identifying potential component failures before products are shipped.

This proactive approach is all about prevention. It’s about making sure that the chances of a product failing are minimized, which, in turn, reduces the risk of costly recalls and damage to the brand’s reputation.

When we talk about risk management, we’re also talking about peace of mind. For business leaders, knowing that their products have undergone thorough testing means they can focus on innovation and growth rather than worrying about when the next big issue will arise.

Build Trust with Quality Component Tester Services

The investment in component tester services goes beyond technical diligence. It’s about embracing a commitment to excellence and trust in every product released.

We’ve uncovered seven compelling reasons that showcase the practicality and necessity of such services in today’s market. As you reflect on these insights, consider the peace of mind and competitive edge that come with knowing every component functions flawlessly.

Continue your exploration of practical, industry-shaping trends and advice. Visit our Technology section for more articles to inspire your next steps.